Track drainage can be defined as the interception, collection, and disposal of water from, upon, or under the track. It is accomplished by installing a proper surface and sub-surface drainage system. As we know, a good track drainage system should essentially ensure that no water percolates into the track at either the surface or the sub-surface levels, and the arrangements for the drainage of sub-surface water should be good and effective wherever required. Track drainage should be handled in two distinctive phases.

Surface drainage Surface water due to rain or snow, or from adjacent areas should be drained off properly by designing well-planned and effective surface drains.

Sub-surface drainage In case water percolates into the formation due to bad soil or such other reasons, the formation gets adversely affected and this has a bearing on the safety and stability of the track. Complete details of the same are given in This article

In the following sections, surface drainage is dealt with in three different stages covering the entire length of the track.

(a) Drainage in mid-sections between railway stations

(b) Drainage in station yards

(c) Drainage of station platforms

Drainage in Mid-sections Between Railway Stations

A drainage system between two railway stations consists of the following features. Side drains Side drains should be provided along the track in cuttings and zero fill locations, where the cess level is not above the ground level. All drains must have an adequate gradient to enable the free flow of the collected water.

Lining of drains Side drain lining is imperative on Group A routes and preferable on other routes, except those routes where the drains are in rocky strata.

Adequate opening under level crossing In order for all the water to flow out of the side drains in cuttings, adequate openings should be provided under level crossings, around trolley refuges, and around the overhead electric masts.

Catch water drain Catch water drains should be provided wherever necessary,in cuttings. Their size should be worked out according to the volume of the water the drain is expected to carry.

No surplus ballast Surplus ballast in the shoulders of the track retards drainage and encourages vegetation growth. All extra ballast should be taken out of the track and stacked in small heaps beside the track.

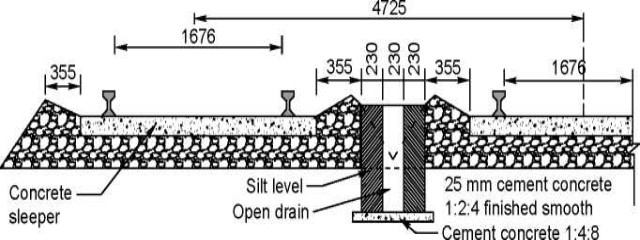

Drainage in Station Yards

When planning the drainage of station yards, the following guidelines should be kept in mind.

Open surface drains Surface drains should generally be left open to make cleaning and inspection convenient. When designing in-yard drains, a velocity range of 0.5 to 1.0 m/s may be allotted for earthen drains and 1.0 to 2.0 m/s for lined (or masonry).

Saucer-shaped drains as mentioned earlier, the longitudinal drains that lie between two tracks should be saucer-shaped with curved sides. However, drains with vertical sides may be provided wherever saucer-shaped drains are not practicable.

Drain top not to be above cess level Normally, the drain top should not be above the cess level for the effective drainage of the ballast bed. However, if it is essential that a drain with a higher top level be provided in order to retain the ballast, weep holes must also be provided at the assumed cess level and the drain so designed that the water it carrier does not flow the base level of the weep holes.

Outflow and slope Wherever there is a proper outfall available at either end of a yard, the longitudinal drains provided should have their slopes facing in the direction opposite to the middle of the yard. This will ensure the minimum size and depth of the drains.

Position of ballast sections the ballast section in station yards should be the same as that on the main line.

Network of cross and longitudinal drains Every station yard should have a network of cross and longitudinal drains, whether earthen or masonry, which allows water collected due to storms to be carried away in the least possible time. The arrangements for surface drainage at water columns and carriage watering points with washing hydrants should be efficiently maintained. At these locations, Water must be adequately trapped and borne away in a pipe or a lined drain.

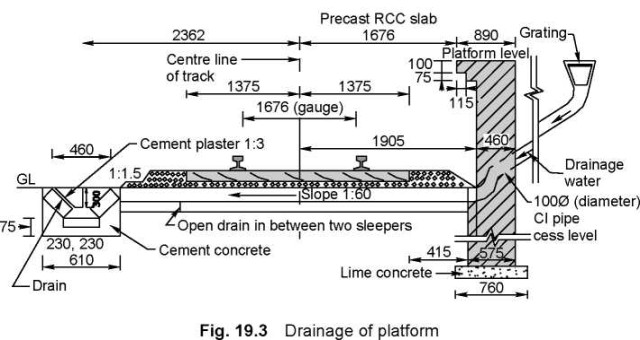

Drainage of Station Platforms

The following points should be taken into account when planning the drainage system of a platform.

Slopes away from track Normally, all end platforms should be sloped away from the track.

Discharge on non-track side All drains from platform shelters, tea stalls, toilets, water taps, etc., should be enclosed in pipes and should normally discharge or release their contents on the non-track side of the platform. Covered longitudinal drains should be provided on the platform, if necessary.

Discharge not towards run-through lines In the case of island platforms, all drains should discharge their contents on the less important side of the track and not towards run-through lines.

Sub-surface Drainage

Water normally reaches the sub-surface due to capillary action, seepage from adjacent areas, or percolation of rainwater. When water reaches the sub-surface, it immediately affects the stability of the formation. The situation becomes worse particularly if the soil is bad. A variety of problems arise due to the proximity of the water to the subgrade. The nature of the problems faced and the remedial measures for the same have been discussed in detail in this article. The various sub-drainage systems used under different conditions are briefly summarized here.

Provision of inverted filter Some sub-drainage systems consist of a blanket of a non-cohesive graded material, which acts as a capillary break.

Paving of catch water drains the entrance of water into the subgrade can be checked by constructing effective catch water drains that are duly paved.

Provision of sand piling Some drainage systems are provided with an adequate number of sand piles of a diameter of about 20 cm. This improves sub-surface drainage.

Drainage of water pockets by perforated pipe Perforated pipes with a diameter of about 30 cm are provided at appropriate places to drain off the water pockets

Cement grouting Cement can be used to grout the water pockets so as to ease the situation.

Drainage of water pockets by puncturing holes In special situations where water is trapped in ballast pockets because of an impervious layer that lies over a good pervious layer, puncturing holes into the impervious layer can help drain away the water.

Requirements of a Good Track Drainage System

A good drainage system should satisfy the following requirements.

Surface water should not percolate to track One of the basic requirements of a good track drainage system is that surface water from rains and adjacent areas should not percolate and seep into the formation of the track.

Effective side drains the size of the side drains should be adequate with a proper slope, so that they effectively carry all the surface water away.

Longitudinal drains to be saucer-shaped the longitudinal drains provided between two tracks should preferably have a saucer-shaped cross section so that they can collect water from both sides.

Provision for clearing and inspection the drains provided for drainage should be such that they can be inspected and cleared periodically.

Drain top to be below cess level Normally, the drain top should not be above the cess level for the effective drainage of the ballast bed.

No erosion of banks the flow of water along the slope and across the track should not cause erosion of the banks or the slopes of the banks.

Formation to be of good soil Ideally, the formation and subgrade should be made of a pervious, coarse-textured soil. Such soils are more permeable, retain less capillary water, and respond more favourably to a surface drainage system.

Proper sub-surface drainage Arrangements should be made for a good subsurface drainage system to drain off the water being retained is the track. This is more relevant in the case of defective formations.

Proper outfall Longitudinal drains should be designed so as to provide a proper outfall, from where the water can eventually drain off.

Special arrangements for waterlogged areas and other difficult situations A good track drainage system should have special arrangements for the drainage of waterlogged areas and for all other related perennial problems.

Need for Proper Track Drainage

Water is the greatest threat to a railway track, and the most prominent factor that adversely affects track maintenance is improper drainage. Excess water affects the stability of the embankment, and the bearing capacity of the soil and its resilience to shear gets considerably reduced. Railway engineers give maximum importance to the proper drainage of the track and the need to do so is felt because of the following concerns.

Settlement of embankment Excess water may cause the embankment to settle.An unequal settlement may lead to variation in cross levels as well as longitudinal levels thereby affecting the safety and riding quality of the track.

Reduction in bearing capacity the bearing capacity of the soil as well as its resistance to shear diminishes due to excess water in the soil. This in turn leads to numerous problems and finally affects the safety and stability of the track.

Failure of embankment the percolation of water in the embankment increases the weight of the soil on the one hand and reduces its bearing capacity and shear resistance on the other. This makes the formation unstable. This is a common reason for the failure of embankments, which occurs in the form of slips.

Formation of ballast pockets Excess moisture leads to punctures in the formation. The constant hammering action of running trains causes the sleepers to move up and down, resulting in ballast pockets, pumping sleepers, and other such problems. All these factors lead to poor riding quality.

Shrinkage and cracking of banks the embankment soil cracks and shrinks once excess water dries up. The problem becomes acute in the case of poor soils. This in turn leads to many problems such as the loss of ballast in the cracks and uneven settlement, which have an adverse effect on track maintenance.

Adverse effects of black cotton soil There are certain soils, such as black cotton soil, which become plastic in nature due to the accumulation of excess water. The formation shrinks due to change in moisture content. The bearing capacity of the soil is greatly reduced due to the excess water. These problems imperil the safety of the track.

Formation of slush Slush is formed due to the dynamic load of running trains. It is forced out, thus badly clogging the ballast. This makes the maintenance of the track very difficult.