Creep is defined as the longitudinal movement of the rail with respect to the sleepers. Rails have a tendency to gradually move in the direction of dominant traffic. Creep is common to all railway tracks, but its magnitude varies considerably from place to place; the rail may move by several centimetres in a month at few places, while at other locations the movement may be almost negligible.

Theories for the Development of Creep

Various theories have been put forward to explain the phenomenon of creep and its causes, but none of them have proved to be satisfactory. The important theories are briefly discussed in the following Article.

Wave Motion Theory

According to wave motion theory, wave motion is set up in the resilient track because of moving loads, causing a deflection in the rail under the load. The portion of the rail immediately under the wheel gets slightly depressed due to the wheel load. Therefore, the rails generally have a wavy formation. As the wheels of the train move forward, the depressions also move with them and the previously depressed portion springs back to the original level. This wave motion tends to move the rail forward with the train. The ironing effect of the moving wheels on the wave formed in the rail causes a longitudinal movement of the rail in the direction of traffic resulting in the creep of the rail.

Percussion Theory

According to percussion theory, creep is developed due to the impact of wheels at the rail end ahead of a joint. As the wheels of the moving train leave the trailing rail at the joint, the rail gets pushed, forward causing it to move longitudinally in the direction of traffic, and that is how creep develops. Though the impact of a single wheel may be nominal, the continuous movement of several of wheels passing over the joint pushes the facing or landing rail forward, thereby causing creep.

Drag Theory

According to drag theory, the backward thrust of the driving wheels of a locomotive has the tendency to push the rail backwards, while the thrust of the other wheels of the locomotive pushes the rail in the direction in which the locomotive is moving. This results in the longitudinal movement of the rail in the direction of traffic, thereby causing creep.

Causes of Creep

The main factors responsible for the development of creep are as follows.

Ironing effect of the wheel the ironing effect of moving wheels on the waves formed in the rail tends to cause the rail to move in the direction of traffic, resulting in creep.

Starting and stopping operations When a train starts or accelerates, the backward thrust of its wheels tends to push the rail backwards. Similarly, when the train slows down or comes to a halt, the effect of the applied brakes tends to push the rail forward. This in turn causes creep in one direction or the other.

Changes in temperature Creep can also develop due to variations in temperature resulting in the expansion and contraction of the rail. Creep occurs frequently during hot weather conditions.

Unbalanced traffic In a double-line section, trains move only in one direction., each track is unidirectional. Creep, therefore, develops in the direction of traffic. In a single-line section, even though traffic moves in both directions, the volume of the traffic in each direction is normally variable. Creep, therefore, develops in the direction of predominant traffic.

Poor maintenance of track Some minor factors, mostly relating to the poor maintenance of the track, also contribute to the development of creep. These are as follows.

(a) Improper securing of rails to sleepers

(b) Limited quantities of ballast resulting in inadequate ballast resistance to the

movement of sleepers

(c) Improper expansion gaps

(d) Badly maintained rail joints

(e) Rail seat wear in metal sleeper track

(f) Rails too light for the traffic carried on them

(g) Yielding formations that result in uneven cross levels

(h) Other miscellaneous factors such as lack of drainage, and loose packing, uneven spacing of sleepers.

Effects of Creep

The following are the common effects of creep.

Sleepers out of square the sleepers move out of their position as a result of the track, which finally results in unpleasant rides.

Disturbance in gaps get disturbed Due to creep, the expansion gaps widen at some places and close at others. This results in the joints getting jammed. Undue stresses are created in the fish plates and bolts, which affects the smooth working of the switch expansion joints in the case of long welded rails.

Distortion of points and crossings Due to excessive creep, it becomes difficult to maintain the correct gauge and alignment of the rails at points and crossings.

Difficulty in changing rails If, due to operational reasons, it is required that the rail be changed, the same becomes difficult as the new rail is found to be either too short or too long because of creep.

Effect on interlocking the interlocking mechanism of the points and crossings gets disturbed by creep.

Possible buckling of track If the creep is excessive and there is negligence in the maintenance of the track, the possibility of buckling of the track cannot be ruled out.

Other effects There are other miscellaneous effects of creep such as breaking of bolts and kinks in the alignment, which occur in various situations.

Measurement of Creep

Creep can be measured with the help of a device called creep indicator. It consists of two creep posts, which are generally rail pieces that are driven at 1-km intervals on either side of the track. For the purpose of easy measurement, their top level is generally at the same level as the rail. Using a chisel, a mark is made at the side of the bottom flange of the rail on either side of the track. A fishing string is then stretched between the two creep posts and the distance between the chisel mark and the string is taken as the amount of creep.

According to the prescribed stipulations, creep should be measured at intervals of about three months and noted in a prescribed register, which is to be maintained by the the permanent way inspector (PWI). Creep in excess of 150 mm (6 in.) should not be permitted on any track and not more than six consecutive rails should be found jammed in a single-rail track at one location. There should be no creep in approaches to points and crossings.

Adjustment of Creep

When creep is in excess of 150 mm resulting in maintenance problems, the same should be adjusted by pulling the rails back. This work is carried out after the required engineering signals have been put up and the necessary caution orders given. The various steps involved in the adjustment of creep are follows.

- A careful survey of the expansion gaps and of the present position of rail joints is carried out.

- The total creep that has been proposed to be adjusted and the correct expansion gap that is to be kept are decided in advance.

- The fish plates at one end are loosened and those at the other end are removed. Sleeper fittings, i.e., spikes or keys, are also loosened or removed.

- The rails are then pulled back one by one with the help of a rope attached to a hook. The pulling back should be regulated in such a way that the rail joints remain central and suspended on the joint sleepers.

- The pulling back of rails is a slow process since only one rail is dealt with at a time and can be done only for short isolated lengths of a track. Normally, about 40–50 men are required per kilometre for adjusting creep.

- When creep is required to be adjusted for longer lengths, five rail lengths are tackled at a time. The procedure is almost the same as the preceding steps except that instead of pulling the rails with a rope, a blow is given to them using a cut rail piece of a length of about 5 m.

Creep Adjuster

A creep adjuster is normally used when extensive work is involved. The creep adjuster is set at the centre of the length of the track, to be tackled, with the wide joints behind it and the jammed joints ahead of it. The following steps are adopted.

- Expansion liners of the correct size are put in all the expansion gaps.

- All the keys on this side of the creep adjuster are removed and all fish bolts loosened.

- The creep adjuster is then used to close up the gaps to the required extent by pushing the rails forward. A gap of a few inches is left behind between the rail ends opposite the adjuster.

- The corrected rails are then fastened with keys. After that, the rails on the other side of the adjuster are tackled.

- The operation leaves some of the expansion gaps too wide which are tackled by the creep adjuster when it is set in the next position.

- The corrected rails are then fastened and the adjuster is shifted to the new position.

- The whole process is repeated again and again till the requisite attention has been paid to the entire length of the rail. In the end it may be necessary to use a rail with the correct size of closure (bigger or smaller) to complete the work.

Portions of Track Susceptible to Creep

The following locations of a track are normally more susceptible to creep.

(a) The point where a steel sleeper track or CST-9 sleeper track meets a wooden sleeper track

(b) Dips in stretches with long gradients

(c) Approaches to major girder bridges or other stable structures

(d) Approaches to level crossings and points and crossings

Measures to Reduce Creep

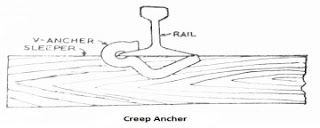

To reduce creep in a track, it should be ensured that the rails are held firmly to the sleepers and that adequate ballast resistance is available. All spikes, screws, and keys should be driven home. The toe load of fastenings should always be slightly more than the ballast resistance. Creep anchors can effectively reduce the creep in a track. At least eight of these must be provided per panel. Out of the large number of creep anchors tried on Indian Railways, the ‘fair T’ and ‘fair V’ anchors, have been standardized for use. The fair ‘V’ anchor, which is more popular, The creep anchor should fit snugly against the sleeper for it to be fully effective. The following measures are also helpful in reducing creep.

(a) The track should be well maintained—sleepers should be properly packed and the crib and shoulder ballast should be well compacted.

(b) A careful lookout should be kept for jammed joints that exist in series. In the case of a fish-plated track, more than six consecutive continuously jammed joints should not be permitted. In the case of SWR tracks, more than two consecutive jammed joints should not be permitted at rail temperatures lower than the maximum daily temperature ™ in the case of zones I and II and lower than (tm – 5°C) in the case of zones III and IV. Regular adjustment may be necessitated on girder bridges.

(c) Anticreep bearing plates should be provided on wooden sleepers to arrest creep, but joints sleepers should have standard canted bearing plates with rail screws.

Creep is the longitudinal movement of rails with respect to sleepers. It is common in all tracks and is a severe type of track defect. In severe cases, it can result in the buckling of the track and can eventually derail the train. Therefore, it is very important to attend to creep immediately after it has been detected. Certain preventive measures can be taken to reduce creep, but it cannot be eliminated completely.